ABS Instead of PVC Edgings? Why a Changeover Pays Off

For years, plastic edgings have become indispensable in furniture making. The most common edging materials are polyvinyl chloride (PVC) and acrylonitrile butadiene styrene copolymers (ABS). Excellent processing characteristics and high material resistance have made ABS edgings the standard for most European carpenters and cabinet makers. If you are still applying PVC edgings, you can find out here why it is worth to make the switch.

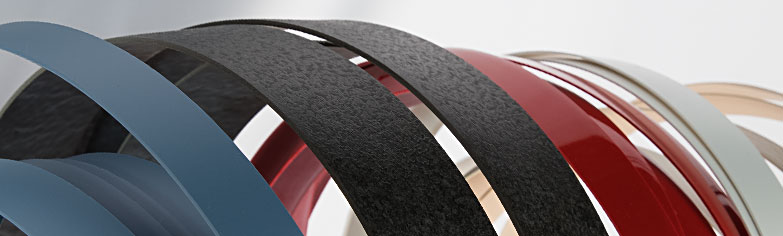

There are hardly any differences in the visual appearance of ABS edgings and edgings made of PVC. ABS material can be homogeneously coloured in all required plain colours. The surfaces can be lacquered to achieve a great variety of gloss levels: from super matt to high gloss. Because it is not only the look of the edging that is increasingly critical, but also its feel, we deliver ABS edgings with numerous different finishes, such as ash pore, minipearl, Linea structure or wood structured. ABS edgings with a decor shine finish are characterised by a special coating with two different varnishes and gloss levels that give the deeper pores and indentations more shine than the higher areas of the edging. Due to the optical variance existing haptic structures, as with real wood pores, are significantly more striking and sculptural in appearance.

Not only visually, but also in terms of price, there are hardly any differences between ABS and PVC edgings.

Most edgebanding machines show no difference in flush trimming of ABS and PVC. If stress whitening occurs with ABS, try to improve the milling tools by adding one or two blades. You can also exchange the buffing disc for a polishing disc with a sisal leather combination, or carefully warm up only the radius with a hot air gun.

Unpainted ABS edgings are paintable with various PUR (DD) lacquers. Do not use NC lacquers. Please be sure to carry out a test coating in advance. For painting narrow surfaces, we recommend special edgings from our range of varnishable edgings.

Take a look at the OSTERMANN diversity in ABS edgings. It will pay off!

English

English