Fundamentals of Edge Processing

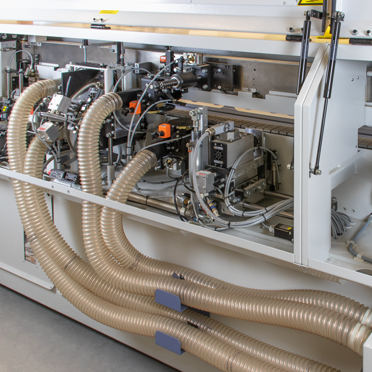

Technology in edgebanding machines is becoming increasingly complex. We have an answer for every type of machine and any kind of technology: with edgings, cleaners and hotmelt adhesives. To achieve a perfect result, you should always follow these rules:

1. Have the Machine Serviced Regularly

A perfect edging result depends on a perfect coordination of all parameters.

- a sharp scraper is crucial

- have the machine checked once or twice a year

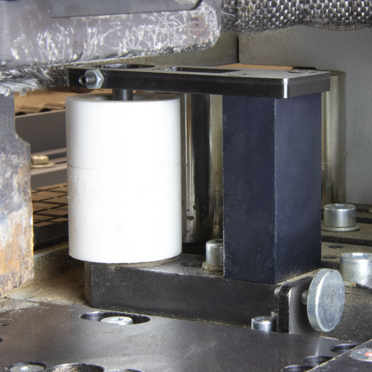

2. Pressure Rollers Accurately Adjusted?

Can you see the glue roll's application pattern in the glue film on the board?

Possible reasons:

- pressure rollers not accurately adjusted

- glue has cooled down too much

- distance between workpiece and glue applicator roll is too small

Solution: If you cannot check the setting by yourself, call in a technician.

The gluepot should be cleaned routinely!

This is how it's done:

Empty the gluepot, switch off the heating system, pour cleaner into the basin while it is still hot and until all incrustations are covered, and leave to act for approx. 20 - 30 minutes. If necessary, you can heat up the hotmelt vessel again briefly. Finally, remove the cleaner through the drain of the gluepot.

Tip: Always remove adhesive incrustations at the edge of the gluepot immediately.

4. Temperature in the Gluepot

Often the temperature display for the hotmelt gluepot does not show the actual temperature. A few degrees Celsius deviation to the manufacturer's recommendation, however, make a big difference.

Tip: Check the gluepot's and the glue applicator roll's temperature with a rod or infrared thermometer on a regular basis.

Draught or a too low room temperature will cool down the adhesive at the glue applicator roll before it can join edging and board.

Tip: Check the adhesive temperature at the glue applicator roll with an infrared thermometer as well. If you are wearing a jacket at work, that is too cold. An ideal workshop temperature is 18 - 20 °C.

When boards and edgings are stored in unheated rooms in winter, or when they come from a cold truck, the adhesive's open time is often already exceeded while still in the machine. The adhesive cools down fast on the boards, until it can no longer build enough adhesive power.

Tip: Both materials should therefore be stored in a heated workshop for 24 hours before processing.

7. Retaining Device Fixed?

With some machines, you have to manually adjust the retaining device at the edging feed to the respective edging height. If it is not sufficiently fixated, the edging will warp when glued on.

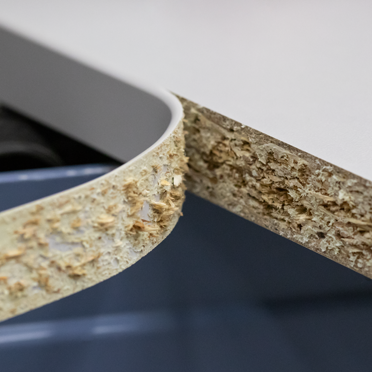

Perform a tear-off test before every new project in order to check all process parameters.

- tear off the edging from the board immediately after application in a 90° angle

- some chips should be pulled out of the board

- essential is the adhesion strength between edging and board

Sure - there is no such thing as a dust-free workshop. This is precisely why you should regularly maintain and clean the machine.

- remove dust and swarf with a vacuum cleaner

- use compressed air only in areas that are otherwise difficult to reach

Tip: If you are often processing high-gloss or super matt surfaces, you can additionally clean the machine parts and in particular the transport tracks with our REDOCOL Teclinex One For All. That prevents dust and dirt from settling in the still fresh glue joint.

10. Store Edgings Horizontally

For a perfect result store the edgings ...

- in a light-protected and dust-free place, i.e. in a closed cabinet

- horizontally: the edging roll stays dimensionally stable, which secures its later processing